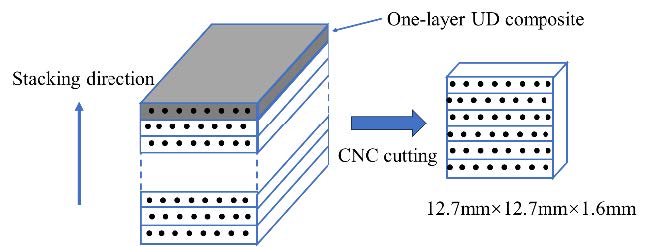

In the present study, heat conductivity of an aircraft-grade BA9916 resin with high-toughness was characterized under the curing condition, so as to support curing modeling for this resin and its carbon fiber composites and avoid timeand labor-consuming experiments for manufacturing process design. Thermal-related properties, including density, curing kinetics, glass transition temperature, specific capacity and thermal diffusivity were measured to obtain thermal conductivity of the material. However, the BA9916 resin was toughened via addition of thermoplastic particles, resulting in much higher viscosity before completely cured than that of common epoxy resins. As a result, it was challenging to directly measure certain thermal properties of the neat resin. To settle this problem, the BA3202 unidirectional carbon fiber composite prepreg with the BA9916 resin was employed as a media to obtain corresponding properties of the resin through experiments and analytical calculation. Derived material properties of the resin were then input to the user-defined material subroutine UMAT to predict thermal response of the composite under various curing conditions, with the maximum error of 6.82% validated via experiments. Hence, the acquired characteristics can be utilized for numerical analysis of various composites composed of BA9916 resin, obviating the need for repeated physical experiments that are time- and resource-consuming.